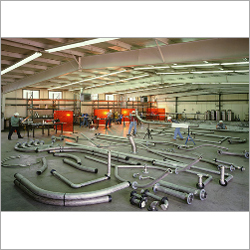

Industrial Fabrication

Product Details:

- Weight Varies with design and size, typically heavy

- Technics Cutting, welding, bending, punching, assembly as per industrial standards

- Fabric Capacity Supports high load bearing depending on specifications

- Fabric Type Metal fabrication

- Shrinkage Negligible (metallic components)

- Fabric Material Mild Steel / Stainless Steel (as per requirement)

- Fabric Texture Smooth finish with robust structural integrity

- Click to view more

Industrial Fabrication Product Specifications

- Supports high load bearing depending on specifications

- As per drawing or customer requirement

- Industrial machinery components, construction structures, customized fabrication works

- Negligible (metallic components)

- Cutting, welding, bending, punching, assembly as per industrial standards

- Mild Steel / Stainless Steel (as per requirement)

- Customized industrial fabrication

- Metal fabrication

- Smooth finish with robust structural integrity

- Varies with design and size, typically heavy

Industrial Fabrication Trade Information

- Gujarat

Product Description

Years of experience in the industry has helped us acquire specialized knowledge of various industrial processes and has enabled us to provide Industrial Fabrication service. In this service, we provide fabrication service of different kinds of firefighting equipment. In order to design firefighting equipment, we use quality approved raw material copper, aluminum, steel, plastic, etc. Our provided service is recognized for professionalism, reliability, timely execution and cost-effectiveness. Also, the service is supervised by our experienced quality professionals in order to maintain a high standard of perfection. Our clients can take advantage of this Industrial Fabrication service from us at highly competitive price.

Tailored Surface Treatments

Choose from painted, powder-coated, or galvanized finishes to match your projects environmental and performance demands. We offer these options to enhance product longevity and protect against corrosion, especially when working with mild steel. Stainless steel options provide intrinsic resistance, making them ideal for harsher settings.

Expert Metal Fabrication and Design

Harness high-quality fabrication using advanced techniques like cutting, welding (MIG/TIG/ARC), and assembly. Our skilled team ensures each component meets precise client specifications, accommodates complex geometries, and offers robust structural integrity. Thickness can be customized between 2mm and 25mm, delivering versatility for various industrial needs.

Comprehensive Industrial Solutions

Serving manufacturers, construction companies, power plants, and warehouses, our metal fabrication products are engineered for heavy loads and demanding usage. Custom packaging solutions protect your order in transit, while our adherence to industrial standards guarantees exceptional reliability and minimal maintenance post-installation.

FAQs of Industrial Fabrication:

Q: How are the fabricated components customized for my project?

A: Each order is fully tailored to your specific drawings, dimensions, and application requirements. We can adjust thickness, length, surface treatment, welding method, and packaging to meet your technical and operational needs.Q: What surface treatment options do you provide and how do they impact performance?

A: Our products can be finished with painting, powder coating, or galvanization, based on your preference. These treatments enhance corrosion resistance and durability, making the components suitable for various environments, with stainless steel providing additional intrinsic protection.Q: When should I choose stainless steel over mild steel for fabrication?

A: Stainless steel is recommended for applications with high exposure to moisture or corrosive substances, or where higher corrosion resistance is critical. Mild steel, with appropriate coatings, is suitable for most structural and industrial applications, offering a cost-effective solution.Q: Where can these fabricated metal components be used?

A: Our fabricated products are suitable for manufacturing industries, construction sites, power plants, machinery plants, and warehouse installations. They serve as essential parts in industrial machinery, structural frameworks, and custom fabrication projects.Q: What is the fabrication process for your metal components?

A: The process involves material selection (MS or SS), cutting, welding (MIG/TIG/ARC as specified), bending, punching, and final assembly. We also apply the desired surface coating before packaging according to your handling and transport requirements.Q: How does your fabrication improve operational efficiency?

A: We deliver structurally robust components with smooth finishes, high load-bearing capacity, and negligible shrinkage. Our customization and precision reduce on-site adjustments and maintenance, helping streamline your project workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Get A Quote

Get A Quote

Call Me Free

Call Me Free